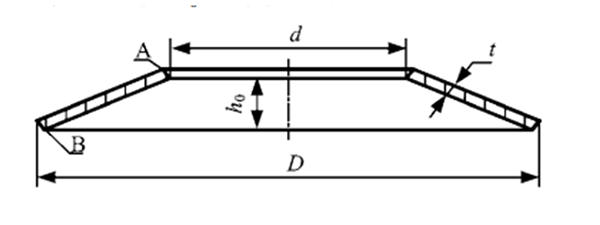

Disc spring is a kind of elastic element with simple structure and compact size. It has the advantages of large bearing capacity, strong shock absorption and easy to obtain different elastic characteristics, and has been widely used in aerospace, metallurgy and machinery. so it has been widely used in aerospace, metallurgy, machinery and other fields. Compared with other elastic elements, the disc spring is also more flexibly, because its combination mode can be changed flexibly, and the force value can also be achieved at a relatively low working height, such as double helix and strong spring. In the case of a relatively low height, it is not as convenient to use as the disc spring, and the maximum force value is not as easy to achieve.

However, due to the limited bearing capacity and deformation of single-piece disc springs, most of them are used in groups. The combination of one head and one inverse is called involution, also called series connection. The stacking combination in the same direction is called superposition, which is also called parallel connection. By adopting different combination methods, various characteristics can be obtained to meet different performance requirements.

Disc Spring Has the Following Different Combinations:

Stacking in Parallel: The load of the stacking disc springs in parallel will be in direct proportion to the number of single disc springs making up the stack.

Stacking in Series: The deflection of stacking disc springs in series will be in direct proportion to the number of single disc springs making up the stack.

Stacking in parallel & series combination: is expressed as I*n stack, such as two pairs of four stacks, three pairs of three stacks and so on.

Disc springs stacks with different thickness and different number of disc springs: Almost any required load/deflection characteristics can be obtained from the different design of stacking combination.

At the same time, however, it should be noted that the more pieces of combined disc springs, the greater the unevenness of load. Therefore, the combined springs with larger diameter and fewer pieces should be used as far as possible to meet the requirements of bearing load and deformation.